Immersion heaters

Immersion heaters serve for heating of fluids, air or gas. They are components of machinery and plants, or mounted into tanks or vessels. According to the individual requirements of our customers, ELMESS-Thermosystemtechnik is offering customized immersion heaters. They are designed and manufactured in high quality industrial design or in explosion proof design according ATEX, IECEx etc. This guarantees a maximum of reliability, safety and long lifetime for your plants.

Design variations

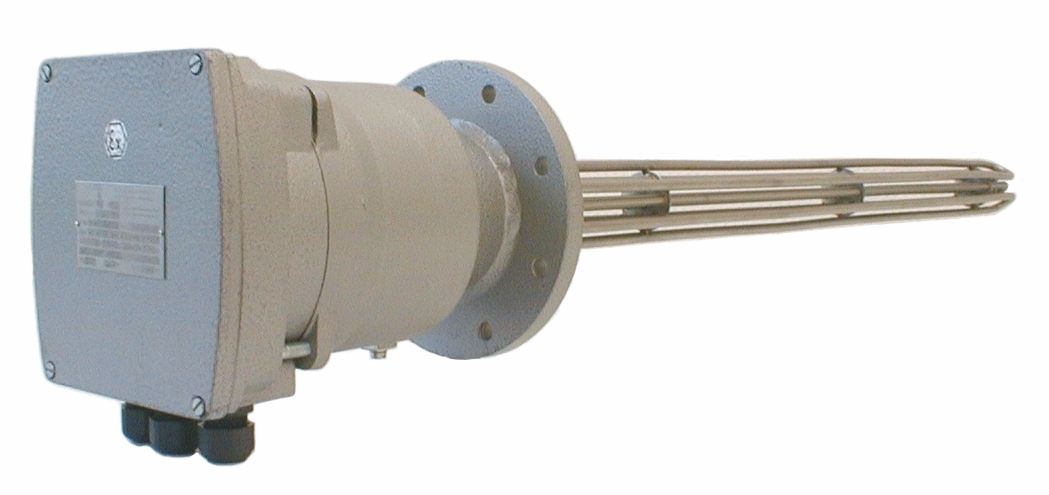

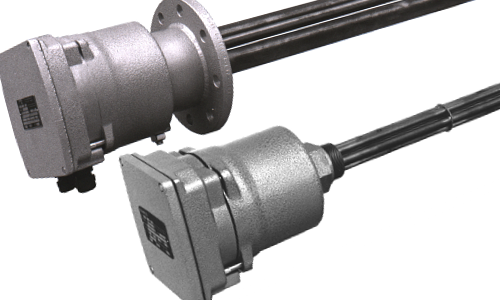

Ex-immersion heater Type DH..B..

Heaters with a bundle of tubular heating elements or cartridge type with withdrawable heating insets. Flameproof heater enclosure made of cast iron, carbon steel with heavy duty painting or made of stainless steel.

For overtemperature protection of the heater and monitoring of the temperature class, a temperature limiter "TSHH" and temperature monitor "TSH" or temperature probes / thermocouples are built-in.

Connection box Ex e for easy installation and maintenance on site.

Design variations with flange or thread connection.

Immersion heaters from ELMESS are used for applications such as the following:

- lubricating oil heaters for turbines, compressors, pumps, refrigeration machines

- heaters for heat transfer oil, heavy oil, fuels

- container heaters for process water and emergency showers

- heating of process gases

- motor anticondesnation heaters

- container and heating chamber heating

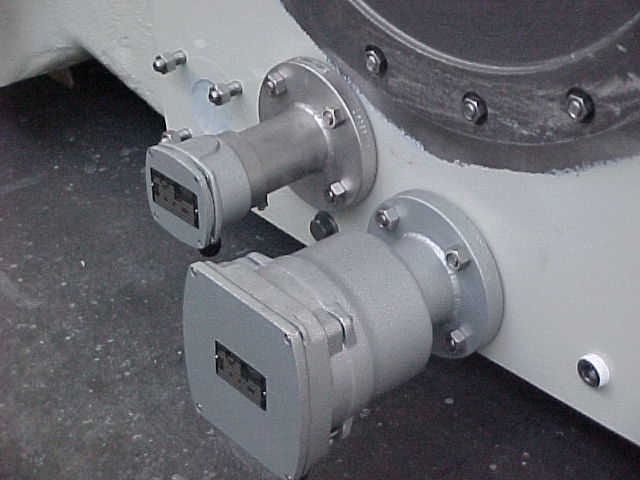

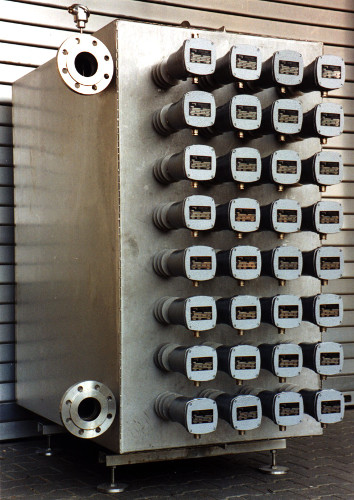

Ex-immersion heater type DH..C..

Ex d or de IIB + H2

Heater for fluids type DHF..C..

Heater for gas type DHG..C..

Flameproof enclosure, welded type made of carbon steel or stainless steel, with built-in temperature limiter and monitor or thermocouple or RTD. Heater bundle made of tubular heating elements or cartridge type with withdrawable heating insets.

Ex e connection box as an option.

- Process heaters

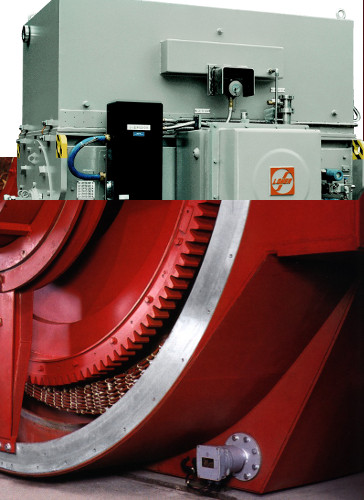

- Tank or lube oil heaters for large machines

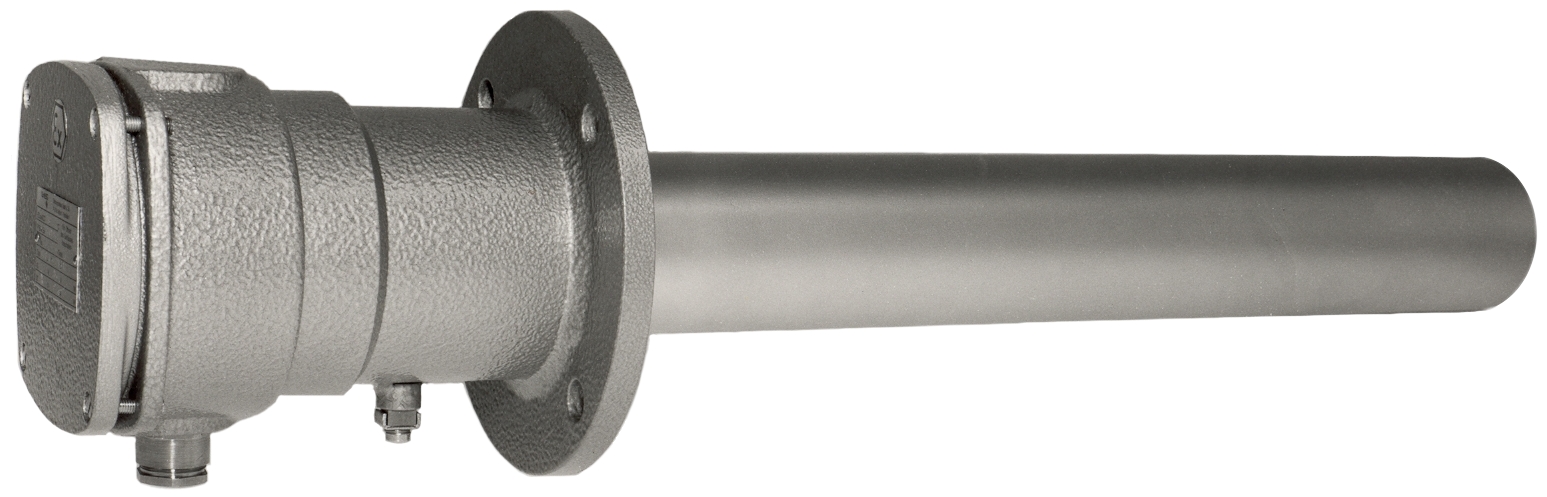

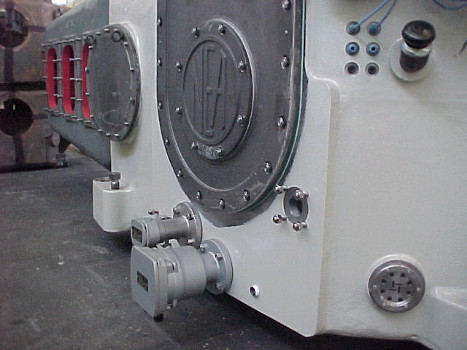

Ex-cartridge heater type DH..A0...

Cartridge type heater with withdrawable ceramic heating inset or with heating bundle of tubular heating elements. Flameproof Ex d enclosure with Ex e connection box. Temperature and level monitoring has to be installed by customer.

Heating of tempering systems, e.g. with heat transfer oil, with external temperature monitoring system.

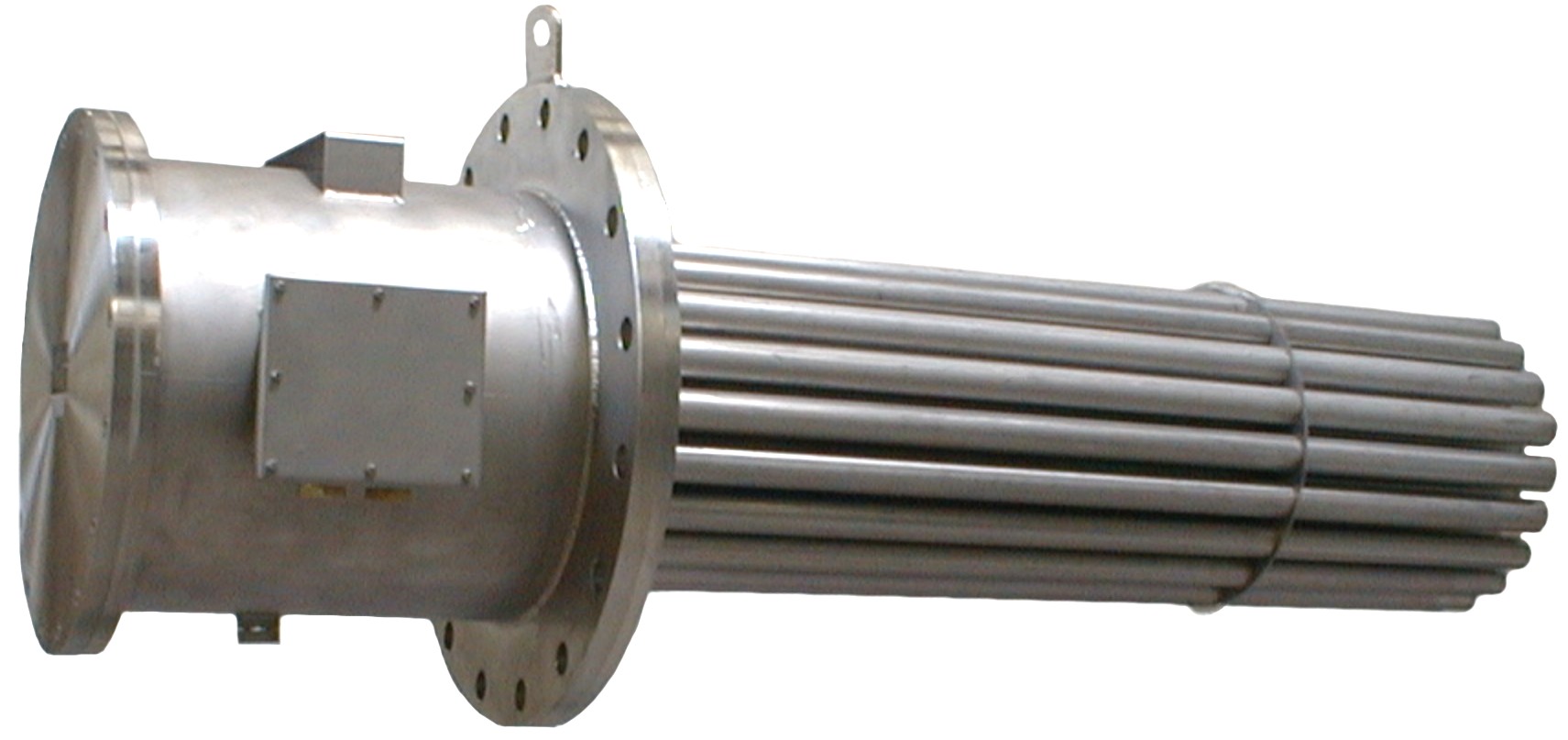

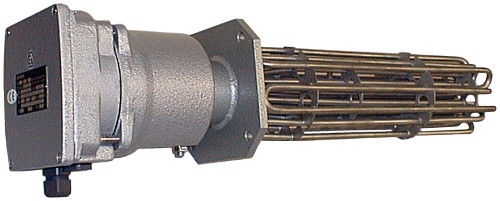

Heater type DHF... for liquid heating

In order to prevent overheating, liquid heaters always have to covered with a sufficient liquid level. This must be guaranteed by means of a level switch which is judged by reliability and function or by comparable measures.

- Lubrication oil systems for gas turbines, compressors, pumps, refrigeration compressors

- Heat transfer oil heaters

- Tanks for oil and fuels

- Tanks for liquids like water or process fluids

- Emergency showers

- Heat exchangers

Heater type DHG... for gases or air

According to the application, a flow monitor can be necessary to prevent the heater from overheating

- Motor anticondensation heaters

- Heater for heating chambers or instrumentation cabinets

- Heating insets for gas heater

Specific surface load

The specific surface load is a measure for the heat transfer onto the heated medium. It must be chosen according to the medium, flow, pressure and mounting conditions as well as the medium temperature and admissible surface temperatures. With a specific surface load which is optimized for the process, a high thermal efficiency will be reached.

Materials

The selection of materials depends on the requirements of the customers, the heated media, the temperature and ambient conditions.

Heating bundle: Stainless steel 321, 316Ti, 316L, incolloy or according to customer's requirements.

Flange or thread connection: Carbon steel, stainless steel 321 or 316 or according to customer's requirements.

Ex connection box made of cast iron or carbon steel with heavy duty painting for all industrial applications, or stainless steel 316.

Pressure vessels

Immersion heaters that are part of apressure vessel are designed, manufactured and inspected according to the pressure vessel code, Pressure Equipment Directive (PED), ASME VIII or other international codes. The selection of category according to PED 2014/68/EU should be advised by the customer, according to the conformity assessment.